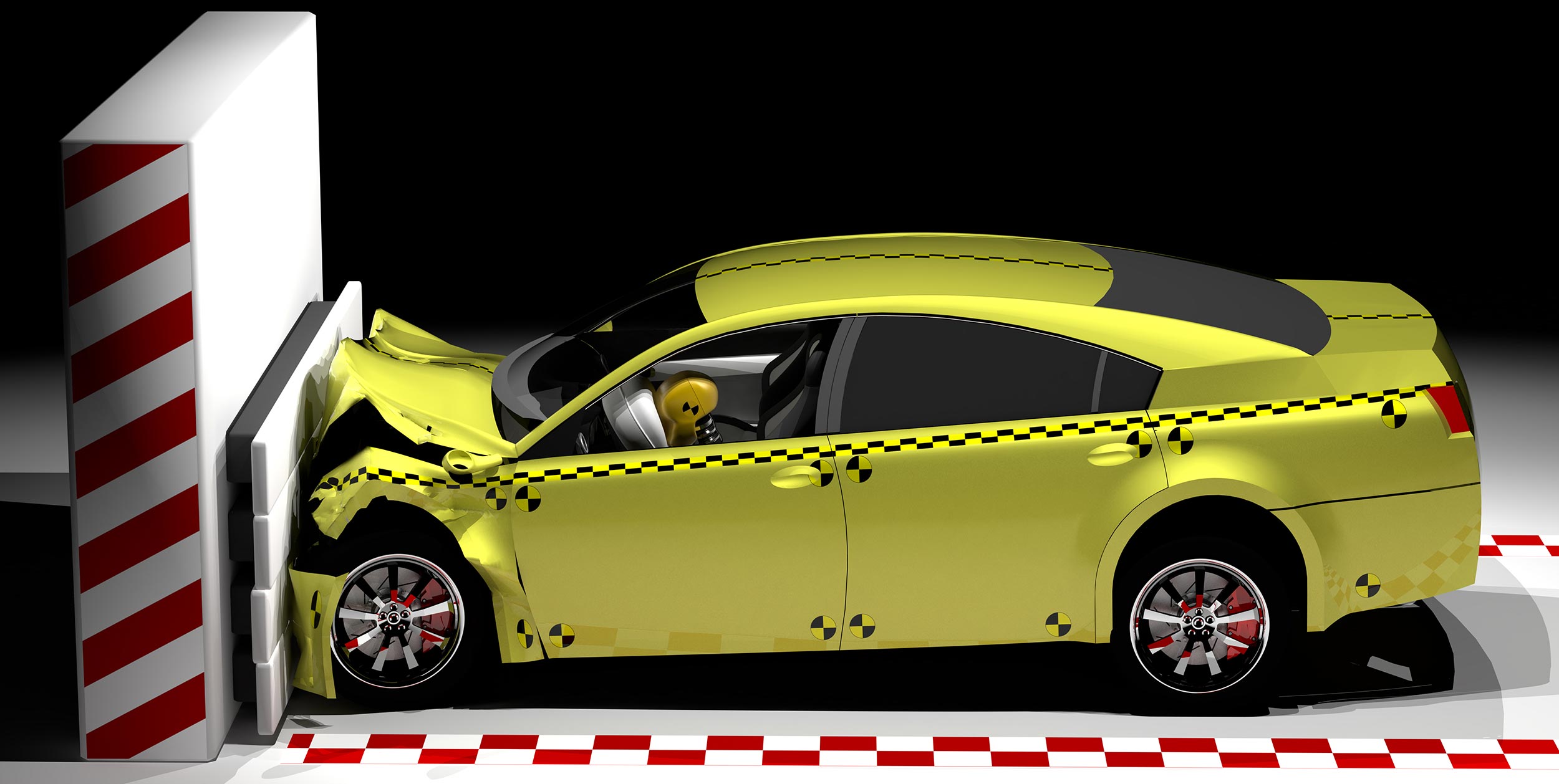

Automotive and Transportation

SmartMetal™ Lightweight SafetyCymat Stabilized Aluminum Foam (SAF) is an innovative material with a combination of characteristics that can be engineered to provide solutions to the challenges facing automakers today. Particularly, Cymat SAF is a cost effective solution to address automotive companies’ competing needs to lighten vehicles, yet improve crashworthiness and occupant protection. SAF is a lightweight material whose cellular structure provides superior energy absorption capabilities. These characteristics are becoming increasingly important as consumer demand and legislation require safer, more efficient, and easier to repair vehicles.

Lightweight

- Can be used on its own, as part of sandwich panel or a plastic composite

Crashworthiness

- Collapses at relatively constant load over large displacements – ideal for absorbing energy

- Non-directional – will absorb energy, regardless of

direction - Does not release poisonous substances at high temperatures

Semi-Structural

- In tubular extrusions – foam stabilizes structure and delays onset of failure, particularly in curved sections or sections experiencing bending loads

- Optimizing tube wall thickness and foam density can minimize of structure

Consistent and Constant Material Properties

- Constant properties over time, operating temperature and moisture range

- Properties do not vary with speed of loading

Noise and Vibration Harshness

- Good sound absorbing capabilities

- Restricts sound transmission by up to 90%

Thermal Insulation

- Non-combustible as set out in ASTM E136-92

- Insulation R-values of 20-30

Environmental Impact

- 100% recyclable

Applications

Some Specific Applications:

Crash Box

- Being considered by many European

auto makers as a means of minimizing damage to a car in an accident Foam-filled tube between bumper and frame of the body can absorb the energy of a low-speed impact before serious damage occurs

Reinforcing Pillars (A, B, C pillars, front rail, etc)

- SAF in a pillar stabilizes the structure and allows it to absorb more energy

Cymat was part of a partnership headed by Tomasz Wierzbicki, Professor and Director of the Impact and Crashworthiness Laboratory at the Massachusetts Institute of Technology. In a three-year research program that included industrial partners such as Volvo, Honda and Ford, MIT concluded that Aluminum Foams have great potential for increasing energy absorption in

The following are excerpts from two research reports on foam-filled tubes:

Report 33 – June 2000: Bending Collapse of Thin-Walled Beams with Ultra-light Filler: Numerical Simulations and Weight Optimization. (Chen, Wierzbicki and Santosa)

“The optimized specific energy absorption of foam-filled beams is about 60% higher than that of non-filled beams for the specific target energy absorption levels. This substantiates the argument that the foam-filled members are superior to non-filled ones in the light of weight-effective energy absorption.”

Report 34 – May 2000: Effect of the Cross-Sectional Shape on Crash Behaviour of a 3-D Space Frame. (Kim and Wierzbicki)

“The ultra-light metallic foam-filled method appears to be the most effective way to reinforce the member under crush loading.” The study further states, “A more than 600% increase of energy absorbed is achieved by foam filling.”

Transportation

In all transportation industries a main goal in design is to make the vehicle safer. Potential applications for Cymat Stabilized Aluminum Foam (SAF) in terms of this goal include:

- Improving the energy management in the front ends of truck and trains

- Improving the internal occupant protection in the passenger compartment

- Protecting goods in transit

- Light-weighting to improve fuel economy