Technology

Production Process

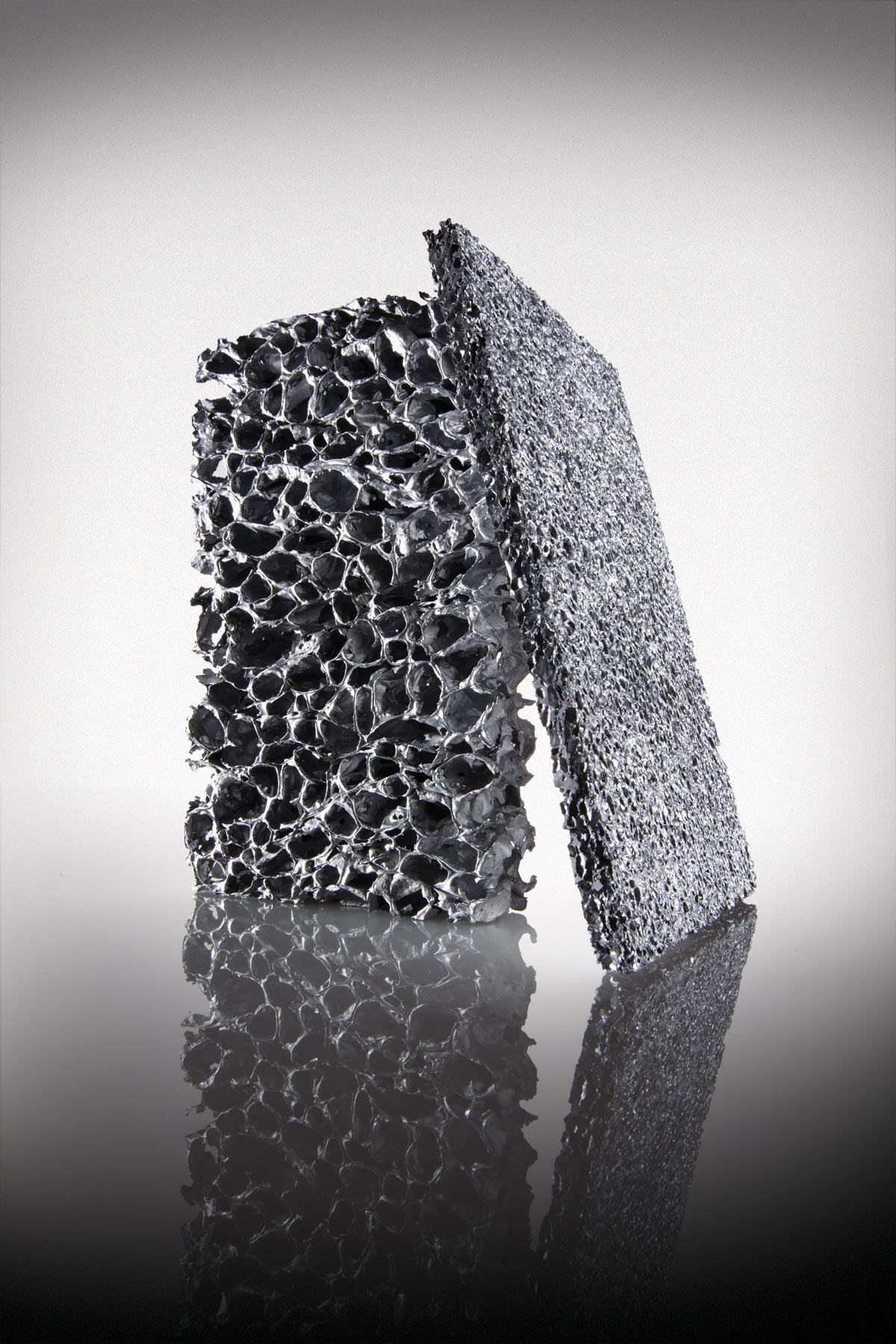

Stabilized Aluminum Foam Process

Liquid metals cannot easily be foamed by bubbling air through them. Drainage of the liquid down the walls of the bubbles occurs too quickly and the bubbles collapse. However, if a small percentage of insoluble particles are added to the melt, the flow of the liquid metal is impeded sufficiently to stabilize the bubbles. This is the theory behind Cymat Stabilized Aluminum Foam.

Production Route

The Cymat process for manufacturing SAF involves 4 basic steps:

Melting the desired aluminum alloy

Transferring the molten material to the foaming box

Injecting gas to form liquid foam

Solidifying the liquid foam into desired shape

This process has the advantages of being scalable and portable, as well as being low in capital cost.

Flat Panel Process (Horizontal Continuous Casting)

The patented process for producing SAF flat panels starts with a metal matrix composite, an aluminum alloy that has ceramic particles added. Once melted, the MMC is poured into a foaming box. By injecting gas in a controlled fashion through a rotating impeller, bubbles are created. The bubbles rise through the liquid MMC and create a foam structure. The foam collects on the surface of the molten material where it can be continuously drawn off to form a sheet. This continuous casting process allows for the most cost-effective production of SAF and creates panel lengths that are endlessly customizable.

SmartMetal™ HD – More Strength Less Weight

“Next Generation” Ultra-Lightweight High Strength Moulded Aluminum Foam